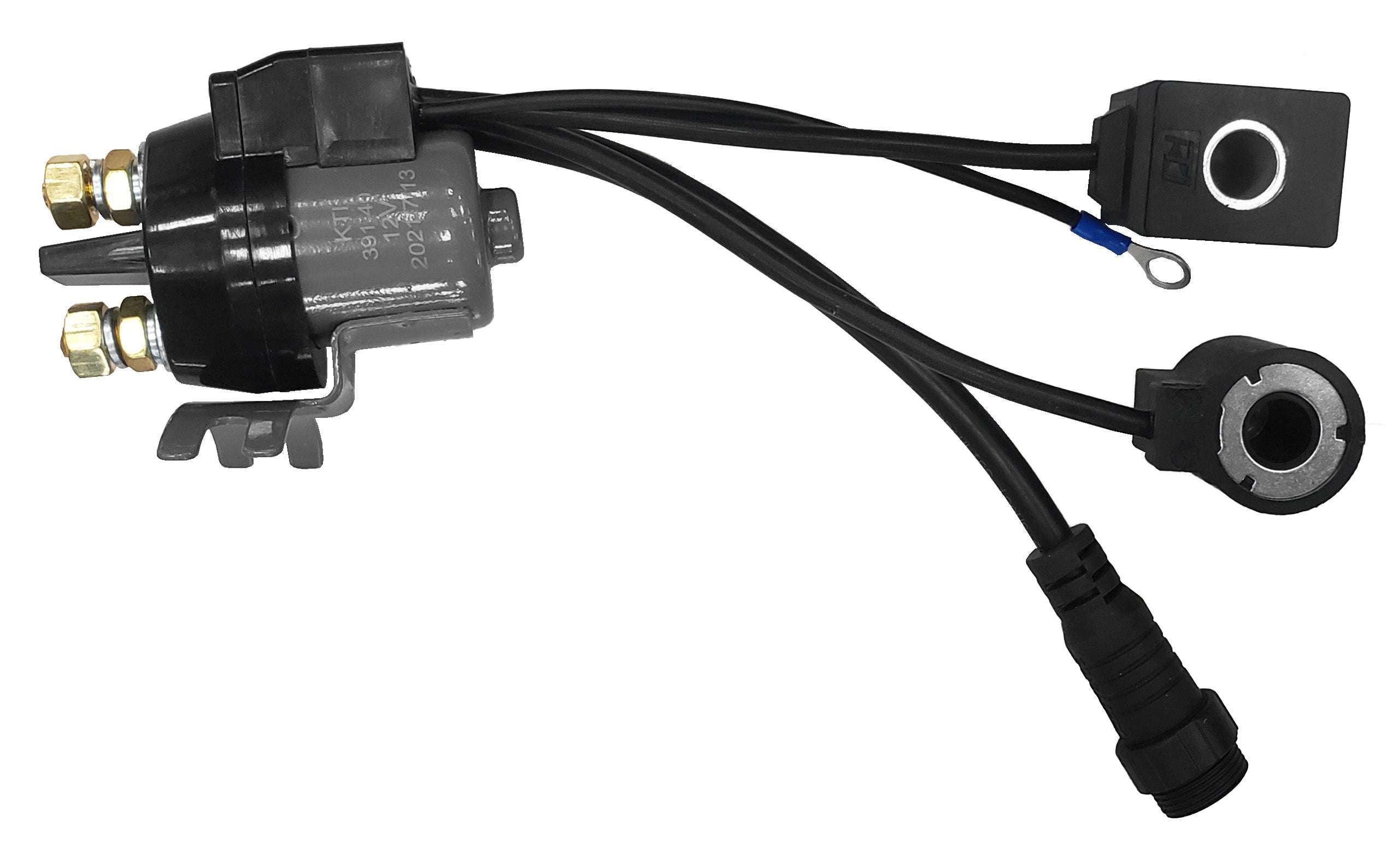

Hydraulics super duty metal hydraulic solenoid 12 volt DC 2512

PT-002186 | 190111

Sale price$74.50

In stockRecently viewed

Affordable Shipping Across Canada & the US

We ship across Canada and the US with a commitment to fair shipping rates, ensuring affordability for all our customers.

Shop Safely with Our Secure Checkout

Experience peace of mind with our trusted and secure checkout process. Serving customers across Canada and the US with reliability and confidence.