How to prevent to damage Trailer Hub Bearings

Bearings are crucial to the safe and efficient operation of a trailer. Understanding the types and knowing how they can be damaged can help in maintaining them properly to avoid costly repairs and ensure long-term use.

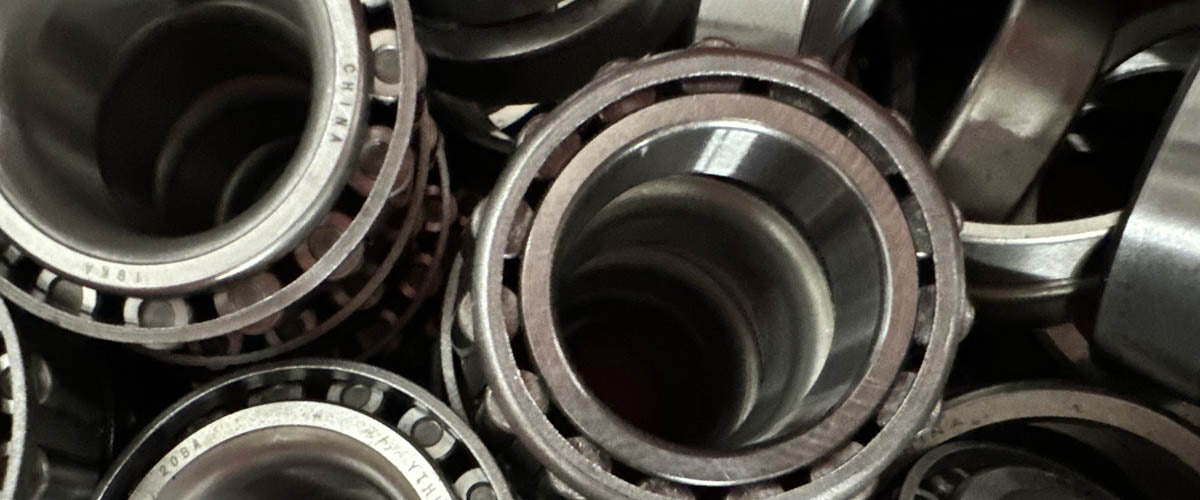

Trailer hub bearings come in various types, each designed for specific load capacities and applications:

- Tapered Roller Bearings:

- Common Use: Most trailers, particularly those carrying heavier loads.

- Design: Tapered rollers that handle both radial and axial loads.

- Ball Bearings:

- Common Use: Light-duty trailers.

- Design: Spherical balls that mainly handle radial loads.

- Sealed Bearings:

- Common Use: High-end trailers or applications where maintenance is minimal.

- Design: Enclosed, preventing contamination and eliminating the need for regular greasing.

- 1. Proper Lubrication

Regularly grease your bearings using the correct type of grease specified for your trailer. This reduces friction and prevents overheating.

Check for grease leaks or drying, and re-grease as necessary. - Avoid Overloading the Trailer

Bearings are designed to handle a specific load. Ensure your trailer is not carrying loads beyond its weight capacity. Overloading puts excessive pressure on the bearings, leading to wear and failure. - Regular Maintenance and Inspection

Periodically check your bearings for signs of wear, rust, or damage.

Look for unusual noises when towing, as grinding or squeaking may indicate bearing issues.

Check the hub temperature after long trips. If it’s excessively hot, it could signal a problem with the bearings.

Failing to regularly inspect and maintain bearings can allow minor issues to become major problems, such as unnoticed wear or insufficient lubrication.

After towing for a while, check the temperature of the hub. If it’s excessively hot, it’s a sign that the bearings may be too tight, improperly lubricated, or otherwise incorrectly installed. - Seal and Protect from Contaminants

Dirt, water, or other contaminants entering the bearings can cause corrosion or create abrasive conditions that wear down the bearing surfaces.

Ensure the bearing seals are intact to prevent water, dirt, and debris from entering the hub.

If towing in wet or dirty conditions, clean and re-grease the bearings after the trip to avoid contamination. - Proper Installation

If bearings are installed incorrectly, such as overtightened, it can cause uneven wear, friction, and eventually damage.

Follow the manufacturer’s torque specifications when tightening the bearings.

After installation, spin the wheel by hand. It should rotate smoothly without any resistance, grinding, or wobbling. If you notice noise or roughness, the bearings might not be seated properly.

Grab the wheel at the top and bottom and try to wiggle it. There should be very little to no play. If the wheel moves excessively, the bearings might be too loose or improperly installed.

A slight amount of play (less than 1/16th of an inch) is normal for some trailer bearings but not more than that.

The spindle nut should be tightened according to the manufacturer’s specifications. Typically, after tightening the nut, you’ll need to back it off slightly before securing it with the cotter pin or lock washer. This ensures the bearings are snug but not overtightened.

Also, check for vibration when towing, as improperly installed bearings can cause an imbalance. - Monitor Speed

Avoid driving at excessively high speeds, as it can cause the bearings to overheat, reducing their lifespan.

By following these preventive measures, you can extend the life of your trailer hub bearings and avoid costly repairs. Regular care and attention will ensure smooth and safe trailer operation.